Under cover, from left Paul Strange, Charlie Cabales, Regan Powell and Brett Farrell at the Cambridge end of the High Level Bridge where work is nearly finished. Photo: Mary Anne Gill

What do the Eiffel Tower and Cambridge’s Victoria Street Bridge have in common?

It is one of those Mastermind questions everyone in town should know, says Waipā Transportation asset engineer Paul Strange pointing towards the lattice steelwork on the High Level bridge.

It shares the design with the Paris tower.

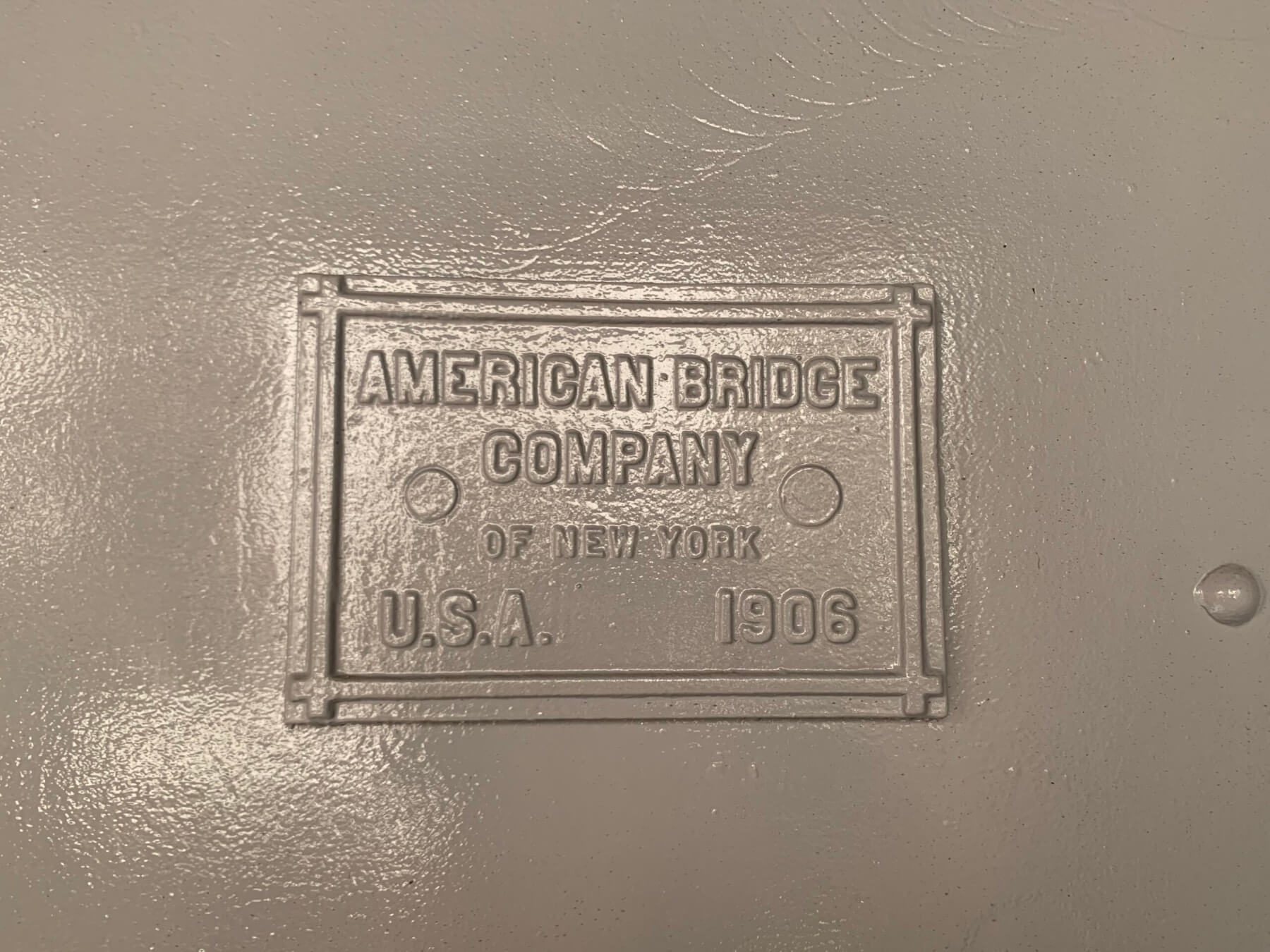

The hinged truss bridge over the Waikato River was prefabricated in 1906 by the American Bridge Company of New York – a freshly-painted imprint in stage one of the $2.6 million painting job confirms the US company’s involvement.

When InterGroup Ltd founder Alan Hill heard Victoria Bridge needed repainting, he told his team they had to get the job.

He was involved the last time it was painted in 1999, commercial general manager Brett Farrell said on a tour of the site for The News last week.

With Farrell and Strange in the site office on the Cambridge side of the bridge for the tour is experienced InterGroup site supervisor Charlie Cabales, who has moved his family to Cambridge for the project.

Technology has changed so much in the ensuing 24 years that this paint job is expected to last more than 40 years.

The type of paint used is the same applied to the North Sea oil rigs and like any paint job, preparation is the key, says Farrell.

Pigeons with their corrosive poo and harsh weather which leads to rusting create the biggest clean up problems and lead to paint deterioration.

“Repainting is a very important aspect of bridge maintenance, making sure it stays in good condition,” says Strange.

The paint provides an important protective layer over the steel, preventing rusting, corrosion, bird roosting and graffiti.

“It’s a complicated engineering job.”

- Paul Strange

- Charlie Cabales, left and Paul Strange.

- From left, Brett Farrell, Paul Strange, Charlie Cabales,.

- Inside the plastic wrapping

- Underneath the High Level Bridge

- Pigeon poo is caustic

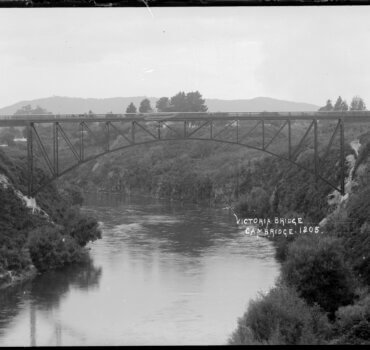

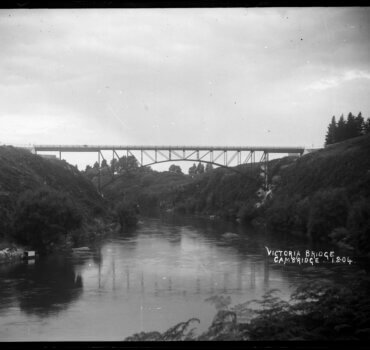

- This Victoria Bridge photo is from the Alexander Turnbull Library.

- This Victoria Bridge photo is from the Alexander Turnbull Library.

The work is being done in stages starting at the Cambridge end. Stage one – the first span – is nearing completion.

Meanwhile scaffolding is already built out towards the arch section with council Water Services staff taking the opportunity to check the watermain under the bridge.

Each stage will be wrapped in the same white plastic sheeting used on leaky buildings.

That will prevent any paint particles or other debris falling into the Waikato River or adjacent vegetation.

Underneath that protective cover Cabales and his blaster painting team clean the bridge and the lattice using high pressure, low volume amounts of water.

They then prepare the surface – repairing any rust, replacing rivets with bolts where necessary – working in the heat and noise from the bridge above them.

And that noise is not going anywhere. The plan is to keep the bridge open throughout the project. Cabeles says it is the pedestrians, cyclists and scooters on the footpaths either side which make the most noise.

And to those who suggest the bridge is not worth the money?

“This bridge will last as long as we maintain it,” said Strange.

Victoria Bridge, a Heritage New Zealand Category One structure, was shipped to New Zealand as a 330-tonne kitset in 1906 and taken by train to Cambridge and Te Awamutu for erection on either side of the Waikato River.

It was the first example of construction using the process of cantilevering the two half arches from each bank.

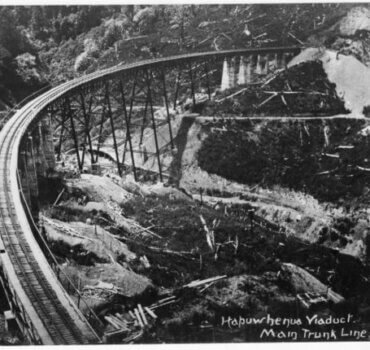

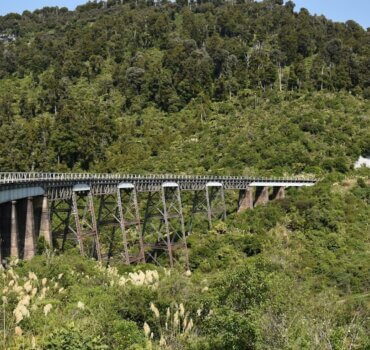

- Hāpuawhenua Viaduct

- Hāpuawhenua Viaduct

The use of lattice steel in bridges was relatively common in the latter half of the 19th century. In New Zealand, it was used in railway bridges like the central North Island Hāpuawhenua and Taonui viaducts and the High Level Bridge. And of course, the Eiffel Tower in Paris.

Some key facts around the work on Victoria Bridge

-

Over 7000 scaffold components will be used in the staging of scaffold.

-

Over 850 Layher lightweight scaffold decks will be used for this project.

-

The lightweight system has a bending strength 24% greater than traditional steel scaffolding tube.

-

The system has lower overall weight which means less load from the scaffolding system itself.

-

Almost 30 tonnes of garnet, grit-sand blasting, will be used to blast the old paint and rust off the bridge.

-

It is estimated that over 2000 litres of paint will be used. The paint has been used on a range of structures, including bridges, oil rigs and chemical plants around the world.